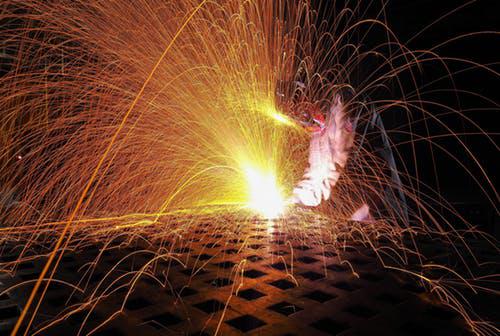

Welding can be a very fascinating hobby and a rewarding profession. Welding is applied in almost every industrial process you can think of, with a scope so wide that most people are completely unaware of what an impact welding makes.

Technological advancements have made welding possible in almost all kinds of environments, including underwater and outer space.

In basic terms, welding is the process of joining two or more metal parts by melting the pieces and adding filler material. The filler is melted and pools between the other pieces, the end result after the materials cool is a strong joint or weld.

Here are the basics that you should have covered before attempting to do any kind of welding of your own:

Types of Welding

There are 4 basic types of welding. These are the most commonly used among the many different styles and techniques of welding. Here’s what you need to know:

Wire-feed Welding

Wire-feed welding machines use a spool of hollow, flux-cored wire that feeds out automatically. Originally developed for welding outdoors at windy construction sites, this welding type is ideal for beginners completing their own projects.

TIG Welding

TIG welding has a non-consumable tungsten electrode to strike the arc and establish the puddle of molten metal. A separate filler rod, held usually in the welder’s other hand, is added to fill the puddle.

MIG Welding

MIG welding uses a solid-core filler wire surrounded with an inert gas like argon, in addition to the traditional wire-feed welder. This kind of welding leaves the weld slag-free and cleaner to be used on stainless steel and aluminum.

Stick Welding

Stick welding involves a flux-coated metal electrode that melts into the puddle and fills the weld bead, making it faster to use for welding thicker pieces. However, it requires a lot of practice and is unnecessary for household use.

Equipment

Based on the type of welding you want to go for, you’ll be able to pick out which welder is best suited for your needs. Apart from the welder, there are a number of items you need before you even think of starting to weld. You’ll require a welding hood before you do any kind of welding because welding sparks are extremely bright, so you must protect your eyes.

You’ll also need a number of tools such as a hammer, a pair of wire pliers, safety goggles, leather gloves, magnetic level and a grinder. All of these tools are necessary to ensure that your welding project goes smoothly.

How to Weld

Now that you have all the necessary equipment and are familiar with what kind of welding you want to perform, it’s time to start welding. The important thing when it comes to welding is making sure you know the structure you want to make and have done the necessary calculations.

When actually welding, before you can join the two pieces together, you need first to position them correctly. After this, you must perform a task known as “tacking,” which is where you perform smaller welds across the joint that you want to weld to just hold the structure together.

The main obstacle that follows is controlling the “pool” that forms of molten metal while you are welding. You have to ensure that the thickness of this pool remains consistent as you move along the joint you want to weld, so as to avoid poor welding practice.

Got some welding work that needs to be done? Well, we at Metal 2 Sculpture Welding & Fabrication are happy to be of assistance! Welding is an art that takes years to master and we’ve done just that to give you the best the welding world has to offer.

As a steel fabrication company in Denver, we offer you our welding expertise for all your welding and fabrication needs. From custom metalwork to custom aluminum gates, no task is too big or too small! Contact us now to avail our professional welding services.